Friday, 30 August 2013

Product Dis-assembly - Breville "The kinetix Control" BBL605

On the 26th of august we had to disassemble a product given to us by breville. The group that i was in had chosen the blender "the kinetix control". While disassembling the product it was interesting to see how many parts made up the product and all the materials being used to make up 1 blender. Using greenfly was very easy. All you needed to do was input the assembly and all the parts involved in that assembly. Then inputting weight of the part and material type helped determine the final results along with transportation, use and end of life. This gave us the final report which was surprisingly not what we thought. This project took quite a long time to finish but was enjoyable to complete.

Monday, 19 August 2013

Project 1: Accessible packaging week 4 Industry critique

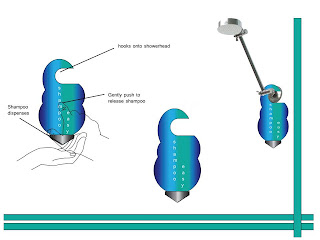

Feedback from Tom: Form is good but a bit blocky look into maybe giving it more of an organic shape by rounding the edges more. Also the nozzle and end of the bottle needs to be changed because it will leave a bit of wastage that i'm trying to avoid. No detail in suction cups and having the lid and nozzle one piece with a live hinge. Look into somehow having a detail in the back of the bottle for the suction cups.

Feedback from Eugenie: The shape is nice but the bottle makes me wanna put my palm on the front making me hit the nozzle. Posters aren't so clear on what its meant to be. Its good to see a consistent theme in the posters the font should be clear not in twirly writing. Overall good concept just need to tweak shape a bit more.

Feedback from Qiuyuan: Doesn't indicate how it will be hung or that its even suppose to be stuck on a wall. The posters don't convey enough information. Not enough detail in the model to show how it will work. Shape needs to be changed.

Feedback from cormack: Need to look into if the suction cups will break or be damaged while pushing it against the wall. Look into maybe putting in a pump or some sort of button to dispense the liquid instead of pushing against the bottle to allow the shampoo liquid to come out. Be careful as some shampoo liquids are thicker then others so that it might not come out as effectively.

Refection: Alter shape to be more organic. Research plastics and look into changing the nozzle shape to point downwards minimizing wastage. Research suction cups and how it will be attached to the final product.

Project 1: Accessible packaging week 3 mock ups

Feedback from Tom: Need to work on the technical aspects as in how it will be attached to the wall and look at more option of shapes. Going in the right direction but need to do more research into what is currently out there and if there isn't any previous products look into why.

Feedback from Ginny: What is the difference between this and a normal soap dispenser? Shape and form currently is good but look into more of why i would buy this product instead of a soap dispenser. Nozzle should be changed so that it points out.

Feedback from Debbie: Heading in the right direction concept wise. not sure about shape at the moment. Looks a bit blocky instead of an organic shampoo bottle. Should make me want to gently push against the bottle so look into something that makes it obvious to push against that part of the bottle.

Lesson from listening to Scott: You need to look in at the overall concept and not put two idea together. They need to flow as one unit and not look like you took one idea and mashed it with another. They need to have some relevance to each other.

My reflection: I need to look into the form more and look into what type of plastics and processes i would use to complete this project. Also what makes mine special and different from existing products. Look into the technical side more!

Sunday, 18 August 2013

T2: Life cycle analysis videos.

Greenfly

- This program helps us as designers look at our products in a different way and look at the environmental impacts the product will have.

- It also looks at alternatives for the product we are designing to limit the impacts we have on the environment.

- Looks at end of use of each product and give a final report with statistics on the product.

Whole system and lifecycle thinking

- We as designer should look at the product at a whole system to fully define the problem

- We need to then look at the life cycle and assessing the biggest impacts and minimizing them.

- Brainstorming helps come up with many solutions that may help solve the problem at hand and may produce many more problems along the way. We take the best solutions out.

Improving product lifetime

- To improve a products lifetime is to design sustainably and by getting the most out of the materials and energy.

- Products go through a lifecycle- from raw materials – manufacture – use – eventual disposal.

- To maximise a products life we need to extend the use period and have the products lifecycle and entirely closed loop, never needing any virgin materials or causing landfills.

Introduction to light weighting and material reduction

- Products that use less material has less environmental impact. This is because the materials needed are less so we are saving our natural resources and reducing landfills.

- By changing the products structure its can lessen the amount of materials being used.

- Without light weighting costs will be high and will consist of too much unnecessary material.

Green material selection

- Choosing the right sustainable material would be abundant and non-toxic

- It wouldn't also require heaps of energy and resources to be manufactured

- The material also would have good end of life options and wouldn’t drive costs up.

Energy efficient design

- To be energy efficient we need to look at choosing the right technology and energy sources.

- The rate in which we use energy is measured in watts. Energy is measured in joules or kilowatt-hours.

- The power source determines the environmental impacts we have.

Looking at all these videos they have taught me to look at products from start to finish. To truly understand something the whole thing needs to be looked at and all its components within it so that we as designers can do whatever is in our power to reduce our impact on the earth. This is important as we have responsibilities to our consumers and to the world we live in to produce products that are of high quality and sustainable at the same time.

Monday, 5 August 2013

Project 1: Accessible packaging- week 2 concepts

Tutor (Tom):

Concept 1: look at existing products if it exists. Also look at different showers and because it may not work in every shower.

Concept 2: may topple over due to the unstable stand it sits on. Not knowing where the tooth past will dispense so clear indication is required. If tooth paste can come out of the product due to its thickness.

Concept 3: The griping nature of the product may not be good for arthritis sufferers. Jam may not come out unless it really processed.

Feed back from peer 1 ( Matthew Patane): Good research. Explored good ideas, specifically like the shampoo bottle. Might want to explore your "wow" factor for the products what would inspire someone to buy it and then show it off. The toothpaste concept has alot of potential for future designs and exploration.

Feed Back from peer 2 (Debbie Tram) : The second concept i believe has more potential then the others because it explores a new idea and looks at brushing your teeth in a different way. Just needs to refined and looked at more closely with details like where the toothpaste comes out of and the stand.

Lessons from listening to other tutors (Scott) : Should look at existing products and maybe look at trying to experience what problem you are adressing for example arthritis putting on layers of gloves and opening a jar.

My reflection and plan of action for this week: I am going to keep my options open and look into the first two concepts in depth more. I believe these two have the most potential when refined to be something good. This week i shall research and go into shopping centers to look at products that are being offered. As well as looking at other ways to mount the product on the wall without being a permanent thing. Explore some shapes with mockups and finalise a design by monday 12th of august.

Subscribe to:

Posts (Atom)